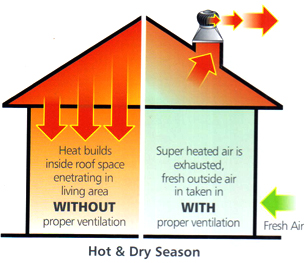

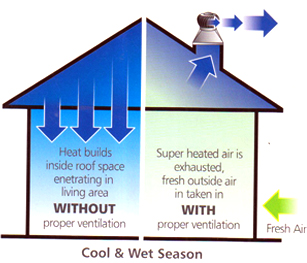

Working Principle

Poonam makes Turbine Air Ventilator work on wind velocity which creates centrifugal action that ultimately spins the blades of ventilator. This results in internal air being extracted and fresh air coming inside. The beauty of this ventilation system is even at negligible wind velocity, the roof ventilator will keep on rotating due to its fly whell type design. The design allows the rotor cage to rotate continuously and keep ventilating on the go. That means, fresh air for you round the clock.

A translucent and opaque colur fibre shett base which allows of natural light in to a building premises. Suits all roof types, adjusts to slopes. Easily installed to deep rib profiles.

- » Absolutely zero recurring cost

- » Maintainance free

- » Eco-friendly & Zero noise level

- » Aesthetic & Attractive look

- » No requirement of Electricity, Generator or Fuel

- » Runs only on Natural wind velocity

- » Satisfied & Pleasure Atmosphere in your premises

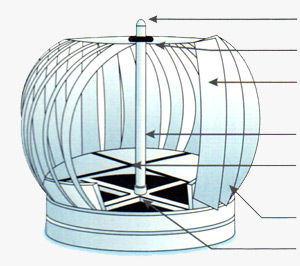

Ventilators Details

- » Stainless Steel thrust bearing.

- » Ensured permanenet allignment. Unique inverted cap design.

- » Corrugated foll formed vanes provide strength, rigidity, positive air flow and weather ability.

- » Typhonic roller bearing system, housing precision upper & lower bearings.

- » Excludes dust, grit and foreign matter and retains unique lubrication in a fully replaceable unit.

- » Fabricated from aluminium/stainless steel.

- » Aluminium turbo ventilators with stainless steel/aluminium spiders and shaft (Assembly are available upon request)

Ventilators Working System

About Ventilator

| Size | 21" mounting |

| 24" mounting | |

| Weight | 21" mounting - Approx 4-50 to 5.50 Kg. |

| 24" mounting - Approx 6-00 to 6.50 Kg. | |

| Blade | Total 36 No. 24 Gauge Aluminium Blade |

| Frame | MS Galvanized Frame |

| Top cover | Stainless Steel / Aluminium |

| Ring | Stainless Steel / Aluminium |

| Mounting | Stainless Steel / Aluminium |

Recommended Air Changes

| Type of building | Air changes per hour |

| Boiler room | 15-60 |

| Engine room | 12-30 |

| Factories(Light) | 10-20 |

| Factories (Heavy) | 20-40 |

| Chemical plant | 30-60 |

| Transformer room | 12-30 |

| Foundry | 10-30 |

Technical Specification

| Wind Velocity | 5KM/HR | 10KM/HR |

| Temperature Diff, in C | 3-5 | 3-5 |

| Dia of Ventilator | Exhaust Capacity | Exhaust Capacity |

| 21" Mounting | 1250 cfm* | 2000 cfm* |

| 24" Mounting | 1300 cfm* | 2150 cfm* |

About Fibre Sheet

| Thickness | 1.5 mm |

| Length | 1800 mm (6 Feet) |

| Wide | Standard Roof |

| Type | Single Piece |

| Available | In standard and translucent and opal requested colour |

How to specify size & determine number of ventilators

*Note :- Number of ventilator depened upon area size and height of premises

To determine number of ventilators required :

{(Volume of shed x no. of air changes)/60} / Exhaust capacity of ventilator.

Volume of shed = length x width x height